The Evolution of Electric Motors: Latest Trends in EV Technology

Electric vehicles (EVs) are revolutionizing the transportation sector as a sustainable solution for decarbonization. At the heart of these vehicles are electric motors, which play a crucial role in powering their movement. As technology continues to advance, there have been remarkable developments in electric motor technology for EVs, driving efficiency, performance, and overall sustainability.

From increased power density to optimized cooling concepts, the latest advancements in electric motors have transformed the EV landscape. Automotive manufacturers and suppliers are constantly pushing the boundaries to create motors that are more efficient, compact, and cost-effective. These innovations have been instrumental in addressing the evolving needs of the electric vehicle industry.

As the demands for electric motors continue to grow, we delve into the latest trends that are shaping the future of EV technology. In this article, we explore the key drivers for electric motor innovations, the advantages of game-changing technologies like axial flux motors and in-wheel motors, the reliability of switched reluctance motors, and the promising SynRM-IPM motors.

Key Takeaways:

- The latest advancements in electric motor technology are driving efficiency and performance in electric vehicles.

- Key drivers for electric motor innovations include the need for reduced installation space, increased power density, optimized cooling concepts, and enhanced controllability.

- Axial flux motors offer higher power density and lower weight density, making them a game-changing technology in the EV sector.

- In-wheel motors revolutionize electric vehicle design by eliminating the need for a separate drivetrain and offering advantages such as torque vectoring.

- Switched reluctance motors are emerging as a reliable alternative for e-mobility applications and do not rely on rare earth metals.

Key Drivers for Electric Motor Innovations

As electric vehicles (EVs) gain momentum in the transportation industry, innovations in electric motor technology play a key role in enhancing their performance and efficiency. The continuous development and improvement of EV motors are driven by several factors that cater to the unique requirements of the electric vehicle sector.

One of the primary drivers for electric motor innovations is the need for reduced installation space. With limited room available in the compact design of electric vehicles, manufacturers are constantly striving to develop motors that occupy less space while delivering optimal performance.

Increased power density is another crucial driver as it allows for higher torque and power output from a smaller motor size. By optimizing the design and incorporating advanced materials, EV motors can achieve higher power densities, resulting in improved vehicle performance and acceleration.

Optimized cooling concepts are also essential for electric motor innovations. As EV motors operate under demanding conditions, efficient cooling systems are necessary to maintain optimal performance and prevent overheating. Innovations in cooling technologies ensure that the motors remain within a suitable temperature range, thereby enhancing their longevity and reliability.

Enhanced controllability is a key aspect that drives electric motor innovations. EV motors must be capable of adapting to various operating conditions, such as frequent starting, stopping, and accelerating. Advanced control algorithms and motor control units enable smooth and precise motor performance, enhancing the overall driving experience.

Moreover, the shift towards using fewer rare earth metals in electric motor construction promotes further innovations. Rare earth metals are often expensive and environmentally challenging to extract. By reducing their reliance on rare earth metals, manufacturers can develop more sustainable and cost-effective motor solutions for electric vehicles.

In summary, the key drivers for electric motor innovations in the EV industry include the need for reduced installation space, increased power density, optimized cooling concepts, enhanced controllability, and the shift towards using less rare earth metals. These drivers push manufacturers to develop lightweight, highly efficient, and adaptable EV motors that meet the evolving requirements of the electric vehicle market.

| Key Drivers | Description |

|---|---|

| Reduced installation space | Develop motors that occupy less space in compact EV designs |

| Increased power density | Achieve higher torque and power output from smaller motor size |

| Optimized cooling concepts | Ensure efficient cooling systems to maintain optimal motor performance |

| Enhanced controllability | Adapt to various operating conditions with advanced control algorithms |

| Shift towards using less rare earth metals | Promote sustainability and cost-effectiveness in motor construction |

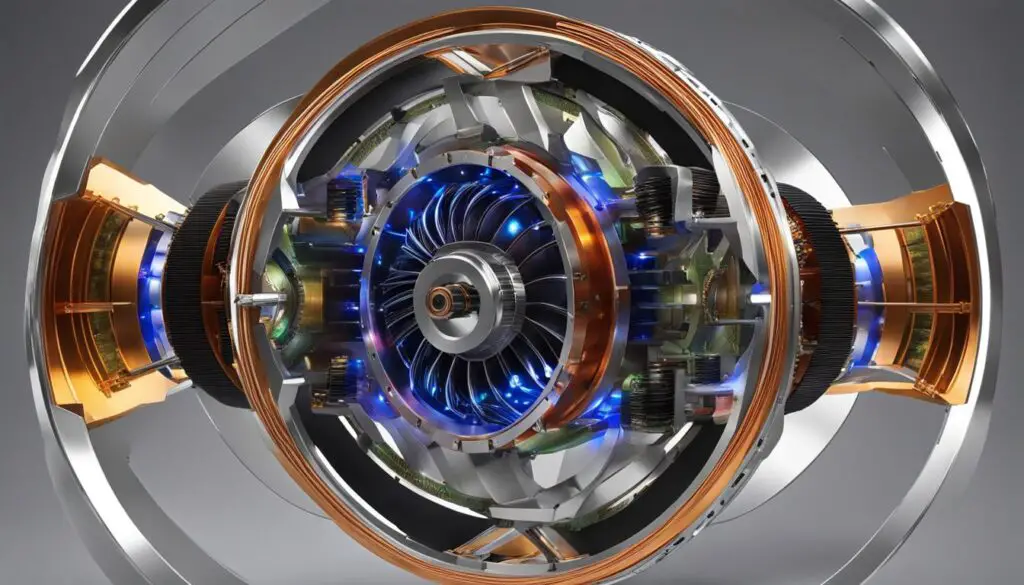

Axial Flux Motors: A Game-Changing Technology for EVs

Axial flux motors are revolutionizing the electric vehicle sector with their numerous advantages over traditional radial flux motors. These motors offer higher power density and lower weight density, making them a preferred choice for electric vehicles. The magnetic flux in axial flux motors runs parallel to the axis of rotation, enabling better power delivery and improved efficiency.

Renowned automotive manufacturers, including Mercedes and Renault, have recognized the potential of axial flux motors and expressed interest in integrating them into their electric vehicles. The advantages offered by axial flux motors make them a game-changing technology for the electric vehicle sector.

Let’s take a closer look at the advantages of axial flux motors in the context of electric vehicles:

Advantages of Axial Flux Motors:

- Higher power density: Axial flux motors deliver more power per unit mass compared to radial flux motors, making them ideal for electric vehicles that require high performance.

- Lower weight density: The compact design of axial flux motors allows for reduced weight without compromising power output, contributing to improved vehicle efficiency and range.

- Better cooling capabilities: The axial design of these motors facilitates efficient cooling, ensuring optimal temperature management and preventing overheating during demanding operations.

- Increased torque density: Axial flux motors offer superior torque density, enabling electric vehicles to accelerate quickly and efficiently.

- Space utilization: The compact and lightweight nature of axial flux motors allows for better space utilization in electric vehicle designs, maximizing interior and cargo space.

- Flexible integration: Axial flux motors can be integrated into various electric vehicle configurations, including hybrid, plug-in hybrid, and fully electric vehicles.

The advantages of axial flux motors make them a compelling choice for electric vehicle manufacturers looking to enhance performance, range, and overall efficiency. These motors have the potential to transform the electric vehicle sector, providing sustainable and high-performing solutions for the future of transportation.

In-Wheel Motors: Revolutionizing Electric Vehicle Design

In-wheel motors, also known as hub motors, are revolutionizing electric vehicle design with their direct drive mechanism. These motors can be mounted directly in the wheels, eliminating the need for a separate drivetrain.

In-wheel motors offer several advantages:

- Torque Vectoring: In-wheel motors provide independent control of each wheel, allowing for precise torque distribution. This enables improved vehicle handling, stability, and traction control.

- Improved Space Utilization: By eliminating the need for a conventional drivetrain, in-wheel motors create additional space within the vehicle, which can be used for increased cargo capacity or innovative interior designs.

Companies like Elaphe and Protean Electric are at the forefront of developing in-wheel motor solutions. Elaphe’s L1500 in-wheel motor offers a power output of 110 kW per wheel, while Protean Electric’s ProteanDrive Pd18 offers a power output of up to 80 kW per wheel.

In-wheel motors have the potential to transform electric vehicle performance and design. The direct drive mechanism improves efficiency, reduces energy losses, and simplifies the overall drivetrain system. Furthermore, the integration of in-wheel motors can enhance vehicle dynamics, resulting in a smoother and more responsive driving experience.

Comparison of In-Wheel Motor Solutions

| Company | In-Wheel Motor Model | Power Output per Wheel | Advantages |

|---|---|---|---|

| Elaphe | L1500 | 110 kW | Torque vectoring, improved space utilization |

| Protean Electric | ProteanDrive Pd18 | Up to 80 kW | Torque vectoring, improved space utilization |

In-wheel motors are gaining attention as a promising technology for electric vehicles. As the electric vehicle market continues to grow, the integration of in-wheel motors in mainstream EV models may become more prevalent.

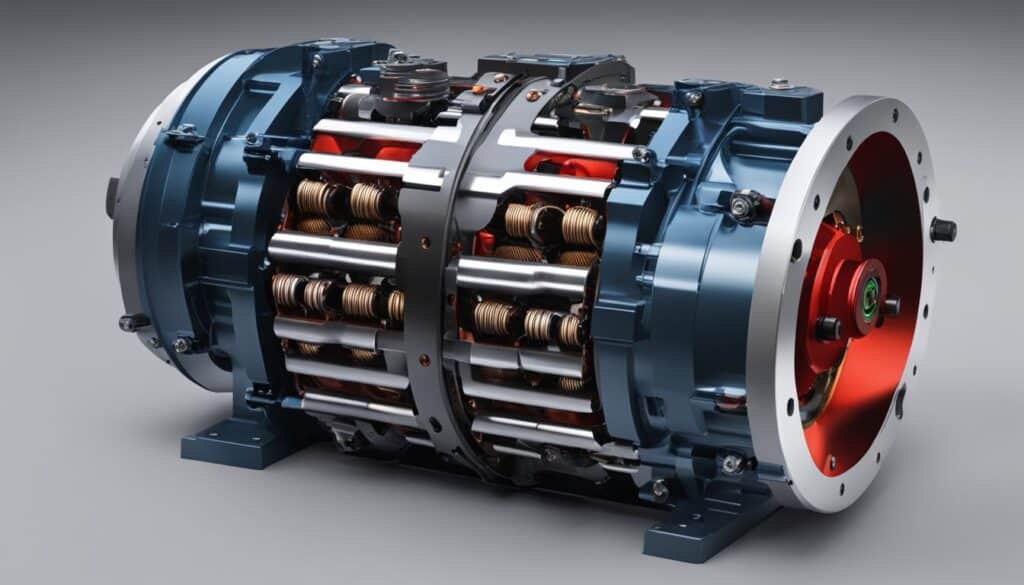

Switched Reluctance Motors: A Reliable Alternative for E-Mobility

Switched reluctance motors (SRMs) are gaining traction as a reliable alternative for e-mobility applications. These motors have undergone extensive testing in zero-fault-tolerant applications for several decades, making them a trusted choice for critical operations. Unlike traditional motors, SRMs do not rely on rare earth metals, making them more sustainable and environmentally friendly.

Recent advancements in power electronics and the Internet of Things (IoT) have further accelerated the adoption of SRMs in various applications. Companies like Enedym Inc. and Turntide Technologies have made significant investments in SRM technology, driving innovation and pushing the boundaries of what these motors can achieve.

One key advantage of SRMs is their exceptional reliability. These motors are designed to operate efficiently under various conditions, providing a stable and consistent performance. This makes them well-suited for demanding applications in the electric vehicle (EV) industry, where reliability is crucial for safe and efficient transportation.

Moreover, SRMs offer a high torque-to-inertia ratio, enabling faster acceleration and improved overall vehicle performance. Their unique design also allows for better control over the motor’s operation, resulting in enhanced efficiency and reduced energy consumption.

SRMs have found applications not only in electric cars but also in other e-mobility sectors such as electric buses and motorcycles. Their ability to handle high-torque demands and adapt to different operating conditions makes them a versatile choice for a wide range of electric vehicles.

Through continued research and development, SRMs are expected to play a pivotal role in the evolution of electric mobility. As the demand for sustainable transportation solutions grows, the reliability and efficiency of SRMs make them a compelling choice for the future of e-mobility.

Advantages of Switched Reluctance Motors in E-Mobility:

- Zero reliance on rare earth metals makes them more sustainable and eco-friendly.

- Exceptional reliability for zero-fault-tolerant applications.

- High torque-to-inertia ratio for faster acceleration and improved vehicle performance.

- Better control and efficiency, resulting in reduced energy consumption.

- Versatile applications in various e-mobility sectors.

Potential Applications of Switched Reluctance Motors in the EV Market:

| Application | Potential Benefits |

|---|---|

| Electric Cars | Improved reliability, efficiency, and performance. |

| Electric Buses and Trucks | High torque for heavy-duty applications and improved energy efficiency. |

| Electric Motorcycles | Fast acceleration, superior control, and energy efficiency. |

| Electric Scooters | Compact design, low maintenance, and sustainability. |

“Switched reluctance motors offer exceptional reliability and efficiency, making them a viable alternative for e-mobility applications.”

SynRM-IPM: The Future of Electric Motor Technology

SynRM-IPM, also known as PMaSynRM, is an innovative electric motor type that combines internal permanent magnets with synchronous reluctance motor rotor construction. This technology offers improved efficiency and torque characteristics, making it an attractive option for small electric vehicle segments. Tesla is one of the pioneers in adopting SynRM-IPM technology in their electric vehicles. The use of high-efficiency and high-density motors is spreading across various industries, including automotive and industrial applications.-

One of the key advantages of SynRM-IPM technology is its ability to achieve higher efficiency compared to traditional electric motors. By combining the benefits of internal permanent magnets and synchronous reluctance motor rotor design, SynRM-IPM motors can significantly reduce energy losses and improve overall system efficiency. This improved efficiency contributes to extended driving range and reduced energy consumption in electric vehicles.

In addition to improved efficiency, SynRM-IPM motors also offer enhanced torque characteristics. The combination of internal permanent magnets and synchronous reluctance motor rotor construction allows for precise control and optimization of torque output. This enables better acceleration, smoother operation, and enhanced overall performance in electric vehicles.

As the demand for electric mobility continues to grow, SynRM-IPM technology is gaining traction in the automotive industry. In addition to Tesla, other major automakers and electric vehicle manufacturers are exploring the potential of SynRM-IPM motors for their vehicle platforms. This technology is particularly suited for small electric vehicles where space and weight constraints are crucial considerations.

The benefits of SynRM-IPM motors extend beyond the automotive sector. Various industries, such as industrial automation and renewable energy, are also adopting this technology to improve energy efficiency and optimize system performance. With its improved efficiency, torque characteristics, and wide-ranging applications, SynRM-IPM is poised to be the future of electric motor technology.

Conclusion

The electric motor market for EVs is witnessing a rapid evolution, driven by advancements in efficiency, performance, and sustainability. Innovations such as axial flux motors, in-wheel motors, switched reluctance motors, and SynRM-IPM motors are reshaping the landscape of the EV industry. These technologies offer various advantages, including higher power density, improved torque characteristics, and reduced reliance on rare earth materials.

The demand for electric motors is projected to experience substantial growth in the coming years, fueled by the global shift towards electric mobility and the increasing adoption of electric vehicles. In response to this demand, original equipment manufacturers (OEMs) and suppliers are placing emphasis on sustainability by optimizing the packaging and integration of electric motors and reducing the use of rare earth materials in their products.

Looking forward, the future of electric motor technology in the EV industry appears promising. Continued advancements and innovations will lead to further improvements in efficiency, performance, and environmental impact. As the electric motor market continues to evolve, it will play a crucial role in enabling a sustainable future for the transportation sector.

FAQ

What are the latest advancements in electric vehicle technology?

The latest advancements in electric vehicle technology include innovations in electric motor technology, such as axial flux motors, in-wheel motors, switched reluctance motors, and SynRM-IPM motors. These advancements focus on improving efficiency, performance, and sustainability in electric vehicles.

What are the key drivers for electric motor innovations?

The key drivers for electric motor innovations in the EV industry include the need for reduced installation space, increased power density, optimized cooling concepts, enhanced controllability, and the shift towards using less rare earth metals. EV motors need to be lightweight, highly efficient, and capable of adapting to various operating conditions.

What are the advantages of axial flux motors in the electric vehicle sector?

Axial flux motors offer significant advantages in the electric vehicle sector. These motors have higher power density and lower weight density compared to traditional radial flux motors. The magnetic flux in axial flux motors is parallel to the axis of rotation, allowing for better power delivery. Axial flux motors have gained interest from industry players like Mercedes and Renault for automotive applications.

How do in-wheel motors revolutionize electric vehicle design?

In-wheel motors, also known as hub motors, revolutionize electric vehicle design by utilizing a direct drive mechanism. These motors can be mounted directly in the wheels, eliminating the need for a separate drivetrain. In-wheel motors offer advantages such as torque vectoring and improved space utilization. Companies like Elaphe and Protean Electric are at the forefront of developing in-wheel motor solutions for electric vehicles.

Why are switched reluctance motors considered a reliable alternative for e-mobility applications?

Switched reluctance motors (SRMs) are considered a reliable alternative for e-mobility applications due to their extensive testing in zero-fault-tolerant applications and their ability to operate without relying on rare earth metals. Recent advances in power electronics and IoT have further boosted the adoption of SRMs in various applications. Companies like Enedym Inc. and Turntide Technologies have made significant investments in SRM technology.

What are SynRM-IPM motors and what advantages do they offer in the EV industry?

SynRM-IPM, also known as PMaSynRM, is an innovative electric motor type that combines internal permanent magnets with synchronous reluctance motor rotor construction. This technology offers improved efficiency and torque characteristics, making it an attractive option for small electric vehicle segments. Tesla is one of the pioneers in adopting SynRM-IPM technology in their electric vehicles. The use of high-efficiency and high-density motors is spreading across various industries, including automotive and industrial applications.

How is the electric motor market for EVs evolving?

The electric motor market for EVs is constantly evolving with new technologies and designs driving advancements in efficiency, performance, and sustainability. Innovations like axial flux motors, in-wheel motors, switched reluctance motors, and SynRM-IPM motors are reshaping the EV industry. The demand for electric motors is expected to grow significantly in the coming years, fueled by the global shift towards electric mobility. OEMs and suppliers are focusing on sustainability by reducing the use of rare earth materials and optimizing the packaging and integration of electric motors.

Source Links

- https://www.idtechex.com/fr/research-article/emerging-electric-motor-technologies-for-the-ev-market/24839

- https://www.futurebridge.com/industry/perspectives-mobility/emerging-electric-motor-technologies-for-the-ev-market/

- https://www.ricardo.com/en/news-and-insights/insights/how-will-e-motors-evolve-in-the-coming-decade