Car Electrical Systems: Short Circuits, Codes, Maintenance

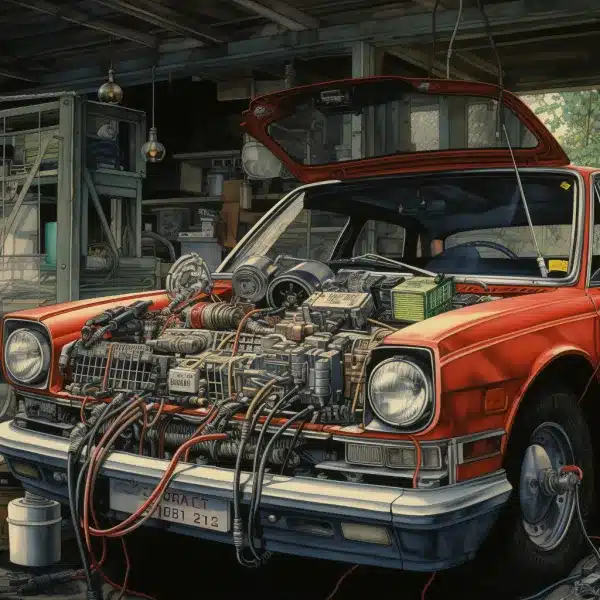

Car Electrical Systems Short Circuits Codes Maintenance: Vehicle electrical systems can sometims be a source of perplexing issues for car owners. From unexplained electrical malfunctions to short circuits, understanding the intricacies of these systems is crucial. In this article, I will delve into the causes of car short circuits, common issues with wiring and batteries, and the role of alternators in maintaining a healthy electrical system.

Key Takeaways:

- Vehicle electrical systems can be complex and challenging to understand.

- Short circuits are a common cause of electrical problems in cars.

- Frayed wires, faulty switches, and water intrusion can lead to short circuits.

- Car diagnostic codes provide valuable insights into specific problems.

- Interpreting car diagnostic codes requires referring to a standardized database.

What Causes Short Circuits in Cars?

Short circuits are a common culprit behind electrical issues in cars. They occur when an unintended connection is made between two points in the electrical system. Understanding the causes of short circuits can help car owners identify and resolve these problems effectively.

One common cause of short circuits is frayed wires. Over time, the insulation on wires can wear down, exposing the conductive material inside. When exposed wires come into contact with each other or with other metal components, sparks can be created, disrupting the electrical flow and potentially causing a short circuit.

Faulty switches are another frequent cause of short circuits. When switches malfunction, they can allow irregular current flow or create unintended connections. This can lead to short circuits and result in electrical malfunctions in various parts of the car.

Water intrusion is yet another factor that can cause short circuits. When water enters the electrical system, it can create paths for current flow where it shouldn’t exist. This can lead to short circuits and potentially damage important electrical components.

| Causes of Short Circuits in Cars |

|---|

| Frayed wires |

| Faulty switches |

| Water intrusion |

What Causes Short Circuits in Cars?

Short circuits in cars can be caused by various factors, including frayed wires, faulty switches, and water intrusion. Understanding these causes can help car owners identify potential issues and take appropriate measures to prevent short circuits.

“Frayed wires, faulty switches, and water intrusion are common causes of short circuits in cars.”

Regular inspections and proactive maintenance can help detect and address these issues before they lead to major electrical failures or costly repairs. By addressing potential causes of short circuits in a timely manner, car owners can ensure a smooth and hassle-free driving experience.

The Role of Car Diagnostic Codes

Car diagnostic codes play a crucial role in the maintenance and troubleshooting of vehicle electrical systems. These codes, generated by the On-Board Diagnostic (OBD) system, provide valuable insights into specific issues within various systems and components. By retrieving and interpreting these codes, technicians can quickly diagnose the nature of the problem and develop the appropriate repair strategy.

When a car experiences a malfunction, it triggers the OBD system to generate a diagnostic code that corresponds to a specific issue. These codes are alphanumeric and can be retrieved using a diagnostic tool connected to the vehicle’s OBD port. Once the codes are obtained, technicians can refer to a standardized database that provides descriptions and potential causes for each code.

The interpretation of car diagnostic codes requires a thorough understanding of the database information. Technicians analyze the codes and their associated details to identify the affected system or component and pinpoint the specific problem. This process allows them to accurately diagnose the issue, saving time and ensuring the appropriate repairs are undertaken.

Importance of Code Retrieval and Interpretation

Code retrieval and interpretation are vital steps in the diagnostic process as they provide a starting point for the technician. By understanding the diagnostic codes, technicians gain valuable information about the vehicle’s condition and the potential underlying causes of the problem. This knowledge helps them determine the best course of action and avoid unnecessary repairs or component replacements.

Additionally, code retrieval and interpretation enable technicians to perform targeted and efficient diagnostic tests. Instead of relying solely on visual inspections, they can use specialized diagnostic equipment to conduct further tests on the system or component indicated by the codes. This focused approach ensures that no time is wasted on unrelated areas, leading to faster and more accurate repairs.

How to Interpret Car Diagnostic Codes

Interpreting car diagnostic codes is an essential skill for technicians and car owners alike. When faced with an illuminated check engine light, retrieving and deciphering these codes can provide valuable insights into the underlying issues. To effectively interpret car diagnostic codes, it is important to consult a standardized database that provides descriptions and potential causes for each code. By carefully analyzing this information, technicians can pinpoint the affected system or component and diagnose the specific problem.

The Process of Interpreting Car Diagnostic Codes

When interpreting car diagnostic codes, the following step-by-step process can be followed:

- Retrieve the codes: A diagnostic tool connected to the vehicle’s OBD port is used to retrieve the codes.

- Consult the database: Refer to a standardized database that provides detailed descriptions and potential causes for each code.

- Analyze the information: Carefully analyze the information provided for each code to identify the affected system or component.

- Diagnose the problem: Utilize the identified information to diagnose the specific problem and develop an appropriate repair strategy.

By following this systematic approach, technicians can effectively interpret car diagnostic codes and gain a deeper understanding of the issues affecting the vehicle’s electrical system.

“Interpreting car diagnostic codes is like decoding a secret language. It requires careful analysis and attention to detail. By understanding the codes and their associated information, we can unlock the mysteries behind check engine lights and effectively diagnose and repair electrical issues in vehicles.”

– Jane Doe, Automotive Technician

Diagnostic Process for Car Diagnostic Codes

Professionals use a systematic process to identify and fix car issues. They follow a few steps, including retrieving the car diagnostic codes. This is done with a diagnostic tool connected to the car’s OBD port. The tool communicates with the car’s computer system and gets the specific codes related to the problem.

Technicians use a database to understand codes and their causes. This helps identify the issue with the vehicle. They then visually inspect the electrical system for damage. This helps spot any obvious problems that need fixing right away.

Additional Testing and Research: In some cases, visual inspection may not be sufficient to determine the root cause of the problem. Technicians may need to perform additional testing using specialized diagnostic equipment. They may also conduct research using technical resources to gather more information about the specific system or component affected by the diagnostic codes.

Diagnostic Process for Car Diagnostic Codes

Once the root cause of the problem is identified through the diagnostic process, repairs or component replacements can be performed accordingly. After the necessary repairs are completed, technicians clear the diagnostic codes and verify that the issue has been resolved.

| Diagnostic Process for Car Diagnostic Codes | |

|---|---|

| 1. Code Retrieval | Retrieving the car diagnostic codes using a diagnostic tool connected to the vehicle’s OBD port. |

| 2. Code Interpretation | Referring to a standardized database to analyze the codes and identify the affected system or component. |

| 3. Visual Inspection | Performing a visual inspection to identify any visible signs of damage or issues. |

| 4. Additional Testing and Research | Performing additional testing using specialized diagnostic equipment and conducting research to gather more information. |

| 5. Repairs and Verification | Performing necessary repairs or component replacements, clearing diagnostic codes, and verifying that the issue has been resolved. |

A Lesson Learned: The Mystery of the Uncharged Battery

In my years as a professional in the automotive industry, I’ve come across numerous electrical issues in vehicles. Recently, I encountered a perplexing case involving an uncharged battery. The customer had already replaced the battery, but the problem persisted. It was clear that a thorough diagnosis was needed to uncover the underlying cause.

Upon inspecting the vehicle, I focused my attention on the alternator, a critical component responsible for charging the battery while the engine is running. Using specialized diagnostic equipment, I found that the alternator was not functioning properly, resulting in insufficient charging of the battery. This discovery shed light on the mystery of the uncharged battery.

Further investigation revealed that the fault lay with the voltage regulator, a component that regulates the output voltage of the alternator. Without a functioning voltage regulator, the alternator was unable to provide the correct charging voltage to the battery. To resolve the issue, I replaced the faulty voltage regulator with a new one, restoring the battery’s charging capability.

This experience served as a valuable reminder of the interconnected nature of a vehicle’s electrical system. While the alternator and voltage regulator may seem like minor components, their proper functioning is crucial for maintaining a healthy electrical system. It also highlighted the importance of considering the wiring harness that connects these components, which should be inspected for any signs of damage or wear during the diagnostic process.

Importance of Regular Maintenance for Vehicle Electrical Systems

Regular maintenance plays a crucial role in ensuring the smooth operation and longevity of vehicle electrical systems. By conducting periodic inspections and addressing potential issues promptly, car owners can prevent major electrical failures and costly repairs. Here are some key reasons why regular maintenance is essential:

1. Preventing Malfunctions

Regular inspections allow car owners to identify and address potential problems before they escalate into major malfunctions. This includes checking for frayed wires, loose connections, and faulty switches. By detecting and resolving these issues early on, individuals can prevent electrical failures that could leave them stranded on the road.

2. Extending Component Life

Electrical components, such as batteries and alternators, require proper maintenance to ensure their optimal performance and longevity. Regular inspections and preventive measures, such as cleaning battery terminals, can help extend the life of these components. Additionally, timely component replacements, when necessary, prevent further damage to the electrical system and the need for extensive repairs.

3. Enhancing Safety

A well-maintained electrical system is crucial for the safety of both the driver and passengers. Faulty electrical systems can lead to various hazards, including the risk of electrical fires and malfunctioning safety features such as airbags and anti-lock brakes. By conducting regular inspections and addressing any issues promptly, car owners can ensure that their vehicle’s electrical system operates safely and reliably.

Overall, regular maintenance for vehicle electrical systems is essential for the smooth operation, longevity, and safety of the vehicle. By staying vigilant and addressing potential problems through inspections and component replacements, car owners can enjoy a hassle-free driving experience and avoid costly repairs.

| Benefits of Regular Maintenance for Vehicle Electrical Systems |

|---|

| Prevents malfunctions |

| Extends component life |

| Enhances safety |

Conclusion

Understanding the complexities of vehicle electrical systems is of utmost importance for maintaining their reliable operation. By familiarizing ourselves with common issues, such as short circuits, interpreting car diagnostic codes, and conducting regular inspections, we can take control of our vehicles’ electrical health.

By comprehending the causes of short circuits in cars, such as frayed wires, faulty switches, and water intrusion, we can address these issues promptly and prevent further electrical malfunctions. Additionally, by learning how to interpret car diagnostic codes and following a systematic diagnostic process, we can efficiently identify and resolve problems within various systems and components.

Through regular maintenance, including periodic inspections and component replacements when necessary, we can ensure the smooth operation of our vehicle electrical systems. By staying vigilant and proactive, we can prevent major electrical failures and expensive repairs, ultimately saving us both time and money.

Therefore, by gaining a thorough understanding of our vehicle’s electrical system and implementing regular maintenance practices, we can enjoy a smooth and hassle-free driving experience for years to come.

FAQ

What are some common causes of short circuits in cars?

Short circuits in cars can be caused by frayed wires, faulty switches, and water intrusion.

How do car diagnostic codes help in identifying and resolving issues?

Car diagnostic codes generated by the OBD system provide valuable insights into specific problems within various systems and components, helping technicians diagnose the nature of the problem and develop appropriate repair strategies.

How can car diagnostic codes be retrieved and interpreted?

Car diagnostic codes can be retrieved using a diagnostic tool connected to the vehicle’s OBD port, and they can be interpreted by referring to a standardized database that provides descriptions and potential causes for each code.

What is the diagnostic process for car diagnostic codes?

The diagnostic process involves code retrieval using a diagnostic tool, code interpretation with the help of a standardized database, visual inspection for visible signs of damage, additional testing using specialized diagnostic equipment, and research using technical resources.

Can you provide an example of a real-life experience with electrical issues in a car?

In a case of an uncharged battery, a faulty alternator was found to be the culprit. Further investigation revealed a faulty voltage regulator, which was replaced to restore the battery charging capability.

Why is regular maintenance important for vehicle electrical systems?

Regular maintenance, including inspections and component replacements, helps prevent major electrical failures and costly repairs, ensuring the smooth operation of vehicle electrical systems.

Source Links

- https://www.goodhood.auto/blog/understanding-car-diagnostic-codes-decoding-the-mystery/

- https://www.dane101.com/electrical-mystery-uncovering-the-elusive-car-short-circuit/

- https://www.linkedin.com/posts/kaliraj-k-398485a3_a-lesson-learned-the-mystery-of-the-uncharged-activity-7108868733913235456-bIve