Flooded Lead-Acid and AGM Batteries: Maintenance, Lifespan

Flooded Lead-Acid and AGM Batteries, In this battery types comparison, we will explore the distinctions between a flooded lead-acid battery and an AGM battery. Both are types of lead-acid batteries but differ in their construction and maintenance requirements.

Key Takeaways:

- AGM batteries are maintenance-free and do not require watering service.

- AGM batteries have a longer service life and can deliver high current.

- Flooded batteries require periodic inspection and maintenance, including adding distilled water.

- Flooded batteries can be damaged in forceful movement and are affected by extreme climates.

- It is important to follow the manufacturer’s instructions for charging and maintenance for both types of batteries.

What is a flooded lead-acid battery?

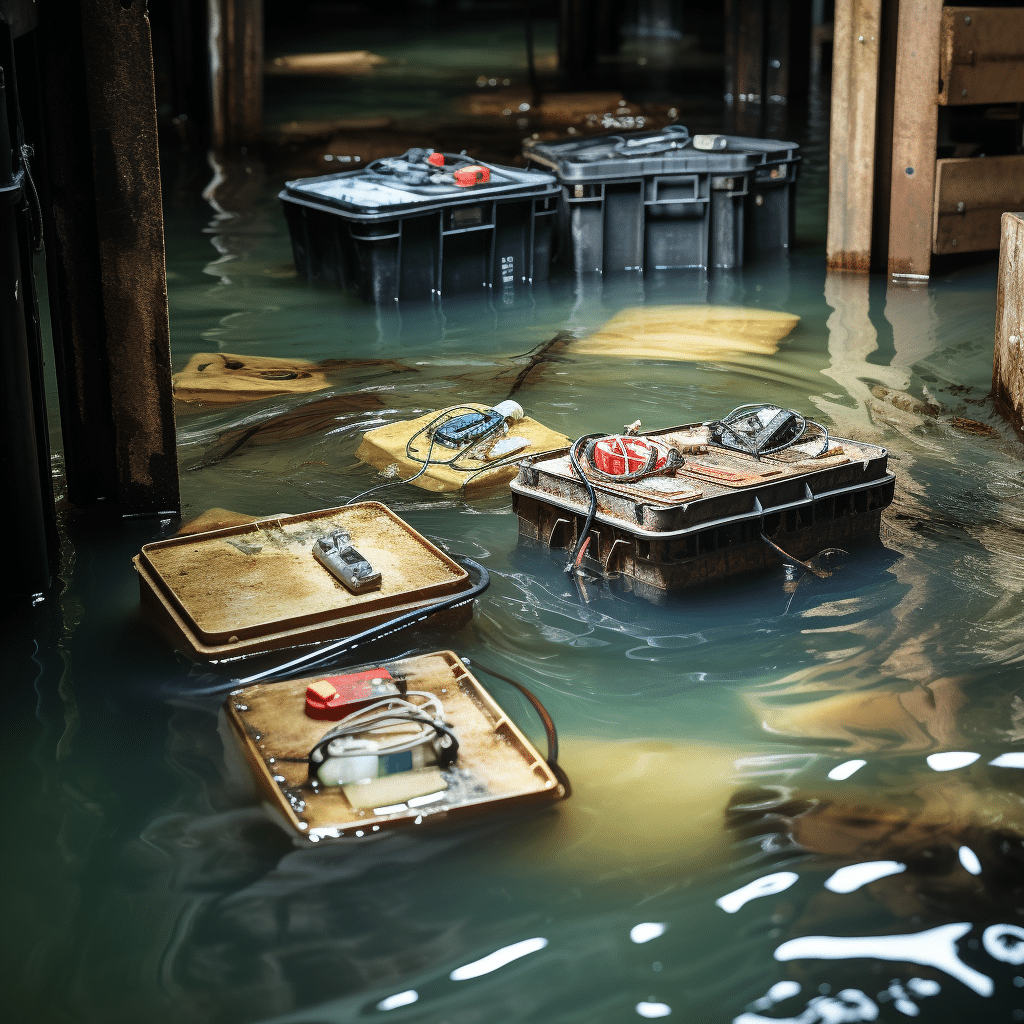

A flooded lead-acid battery is a traditional type of lead-acid battery commonly used in different applications, including car batteries, and requires regular maintenance. These batteries are constructed with multiple lead plates submerged in a liquid electrolyte solution, typically a mixture of water and sulfuric acid, which triggers the necessary chemical reactions for power generation.

To maintain the performance and longevity of flooded lead-acid batteries, periodic maintenance is essential. This involves inspecting the battery regularly, adding distilled water to compensate for evaporation, and adjusting the density of the electrolyte solution. This maintenance ensures that the battery operates optimally and prevents premature failure.

Flooded lead-acid batteries are a reliable and cost-effective option for various applications. However, they do require regular monitoring and care to maximize their lifespan and ensure their proper functionality.

How does a flooded lead-acid battery work?

The operation of a flooded lead-acid battery relies on the interaction between the liquid electrolyte solution and the battery plates, which triggers the necessary chemical reactions for it to function. The battery consists of lead plates submerged in an electrolyte solution, usually sulfuric acid diluted with water. When the battery is connected to a circuit, a chemical reaction occurs at the battery plates, converting chemical energy into electrical energy.

The lead plates within the battery are coated with a paste made from lead oxide, which allows for a larger surface area and enhances the battery’s efficiency. The chemical reactions that occur during battery operation involve the conversion of lead oxide and lead sulfate. When the battery discharges, lead sulfate forms on the plates, and when it charges, the lead sulfate is converted back into lead oxide and sulfuric acid. This cycle of conversion enables the battery to store and release electrical energy as needed.

The key role of the liquid electrolyte solution is to facilitate the movement of ions between the battery plates. As the battery discharges, the sulfuric acid dissociates, releasing hydrogen ions (H+) into the electrolyte solution. These ions combine with the lead sulfate on the plates, forming lead sulfate crystals. When the battery charges, the lead sulfate crystals break down, releasing hydrogen ions back into the solution, which then recombine with the lead oxide, converting it back into lead sulfate. This continuous cycle enables the battery to operate efficiently.

Pros and Cons of Flooded Lead-Acid Batteries

Flooded lead-acid batteries offer an extended lifespan and lower cost compared to other battery types, but they require regular maintenance, can be damaged easily, and are sensitive to extreme climates.

Here are some pros and cons of using flooded lead-acid batteries:

Pros:

- Extended lifespan: Flooded lead-acid batteries generally have a longer service life compared to other battery types when properly maintained. This makes them a cost-effective option in the long run.

- Lower cost: These batteries are more affordable compared to alternative options, making them suitable for applications where budget constraints are a concern.

- Easy maintenance: Regular maintenance is necessary for flooded lead-acid batteries, but the tasks involved, such as adding distilled water and adjusting the electrolyte density, are relatively simple and can be performed by the user.

Cons:

- Regular maintenance: Flooded lead-acid batteries require periodic inspection and maintenance to ensure optimal performance. This includes checking and replenishing the electrolyte level, which involves adding distilled water and adjusting the specific gravity of the electrolyte.

- Vulnerability to damage: These batteries are susceptible to damage if subjected to forceful movement or impact. It is important to handle them with care to avoid any physical harm that can lead to the malfunction of the battery.

- Sensitivity to extreme climates: Extreme hot or cold temperatures can significantly affect the performance and lifespan of flooded lead-acid batteries. It is important to consider the climate conditions of the intended application and take appropriate measures to protect the batteries from extreme weather conditions.

It is important to evaluate these pros and cons when considering flooded lead-acid batteries for your specific needs. While they offer advantages such as extended lifespan and lower cost, they also require regular maintenance and can be sensitive to extreme climates. By carefully assessing your requirements and taking necessary precautions, you can make an informed decision regarding the most suitable battery type for your applications.

| Battery Type | Pros | Cons |

|---|---|---|

| Flooded Lead-Acid Battery |

|

|

What is an AGM battery?

An AGM battery, short for Absorbed Glass Mat battery, is a type of lead-acid battery that features a unique construction, requiring minimal maintenance, and utilizing a special glass mat separator to keep the electrolyte solution contained. AGM batteries are known for their maintenance-free operation, making them an attractive option for various applications, including car battery replacements.

The electrolyte solution in AGM batteries is stored in a “dry” or suspended state within the glass mat. This design ensures that the electrolyte will not spill, even if the battery case is damaged or tipped. The glass mat separator also provides excellent electrical conductivity, allowing the battery to deliver high current when needed.

One of the major advantages of AGM batteries is their long service life. They are designed to withstand deep cycling and perform well even when discharged to 50% of their capacity. This makes them suitable for applications where a reliable power source is crucial, such as in vehicles with multiple electrical accessories or in off-grid solar systems.

AGM batteries

While AGM batteries offer numerous benefits, it’s important to note that they require careful charging. Overcharging an AGM battery can damage it and reduce its overall lifespan. Additionally, AGM batteries typically have a higher upfront cost compared to traditional flooded lead-acid batteries. However, considering their maintenance-free nature and extended service life, the higher initial investment can often be justified.

| AGM Batteries | Flooded Batteries |

|---|---|

| Maintenance-free | Require periodic inspection and maintenance |

| Long service life | Extended lifespan with proper maintenance |

| High current delivery | N/A |

| N/A | Lower cost compared to AGM batteries |

In summary, AGM batteries offer a maintenance-free and longer-lasting alternative to traditional flooded lead-acid batteries. Their unique construction, with a glass mat separator, ensures minimal maintenance and prevents electrolyte spillage. While careful charging is necessary and the upfront cost may be higher, AGM batteries are ideal for applications where reliability, longevity, and ease of use are paramount.

How does an AGM battery work?

AGM batteries operate by utilizing a special glass mat separator to hold the electrolyte solution in a “dry” or suspended state, enabling them to deliver high current and remain spill-proof even under harsh conditions. This unique design ensures that the electrolyte does not leak or spill, making AGM batteries the ideal choice for applications where safety and reliability are paramount.

The glass mat separator acts as a sponge, absorbing the electrolyte and tightly binding it to the battery plates. This prevents the electrolyte from freely flowing, even when the battery is subjected to strong vibrations or placed in unconventional positions. As a result, AGM batteries offer superior resistance to shock and vibration compared to flooded lead-acid batteries.

In addition to their spill-proof nature, AGM batteries have a lower internal resistance and can deliver high bursts of energy when needed, making them suitable for applications that require high current output, such as starting vehicles or powering heavy-duty equipment. Their ability to provide a consistent and reliable power source, even under heavy loads, sets them apart from other types of lead-acid batteries.

The maintenance-free aspect of AGM batteries is another advantage. Unlike flooded lead-acid batteries, AGM batteries do not require regular watering or electrolyte level checks. This makes them a convenient choice for applications where accessibility for maintenance is limited or where regular battery maintenance is burdensome.

| AGM Batteries | |

|---|---|

| Pros | Cons |

|

|

Pros and cons of AGM batteries

AGM batteries offer several advantages such as being maintenance-free, having an extended service life, and delivering high current, but they require careful charging and have a higher upfront cost compared to flooded lead-acid batteries.

One of the key benefits of AGM batteries is that they are maintenance-free, eliminating the need for regular checks and adding distilled water. This makes them ideal for applications where maintenance is complex or access to the battery is limited. Additionally, AGM batteries have a longer service life compared to flooded batteries, making them a cost-effective choice in the long run.

AGM batteries are known for their ability to deliver high current, making them suitable for applications that require a burst of power such as starting an engine. The special glass mat separator in AGM batteries holds the electrolyte solution between the battery plates, allowing it to be stored in a “dry” or suspended state. This prevents spillage, even if the battery case is damaged or tipped, ensuring safety and peace of mind.

However, it is important to note that AGM batteries require careful charging to maintain their performance. Overcharging or undercharging can significantly impact their lifespan and performance. Additionally, AGM batteries perform best when the discharge is limited to 50% of their capacity. While the upfront cost of AGM batteries may be higher compared to flooded batteries, their maintenance-free nature and longer service life justify the investment.

| Pros | Cons |

|---|---|

| maintenance-free | require careful charging |

| long service life | perform best with limited discharge |

| deliver high current | higher upfront cost |

Comparison between flooded lead-acid batteries and AGM batteries

Flooded lead-acid batteries require regular maintenance and have a cheaper upfront cost, while AGM batteries are maintenance-free, last longer, and perform better under specific conditions.

Absorbed Glass Mat (AGM) batteries are maintenance-free. They don’t need watering or inspection like flooded batteries. For applications with difficult maintenance or no regular inspection, AGM batteries can supply high current and last longer.

AGM batteries have a glass mat separator that stores electrolyte solution between plates. Even if the battery casing is damaged or tipped, the electrolyte remains “dry” or suspended. This design improves safety and makes them perfect for harsh vehicles and equipment.

On the other hand, flooded lead-acid batteries, the traditional type of lead-acid battery, require periodic inspection and maintenance. This includes adding distilled water and adjusting the density of the electrolyte. Although they require regular maintenance, if properly taken care of, flooded batteries can have an extended lifespan.

They are also more cost-effective compared to AGM batteries

| AGM Batteries | Flooded Batteries |

|---|---|

| Maintenance-free | Require periodic inspection and maintenance |

| Longer service life | Extended lifespan if properly taken care of |

| High current delivery | Lower upfront cost |

| Electrolyte stored in “dry” or suspended state | Liquid electrolyte solution |

In summary, when choosing between flooded lead-acid batteries and AGM batteries, it is important to consider the maintenance requirements, service life, and performance characteristics that best suit your specific needs. AGM batteries are maintenance-free, have a longer service life, and perform better in applications where maintenance is complex or regular inspection is not feasible. On the other hand, flooded batteries require periodic maintenance but can last longer if properly taken care of. It is crucial to follow the manufacturer’s instructions for charging and maintenance for both battery types to maximize their performance and lifespan.

Tips for choosing the right battery type

To choose the best flooded lead-acid or AGM battery, consider application, maintenance, and price. AGM batteries are good for high-current, maintenance-free solutions. AGM batteries suspend the electrolyte solution, avoiding the need for watering and reducing spillage, even if damaged or tipped. These batteries can take high current and last longer, making them excellent for complicated maintenance applications.

A flooded lead-acid battery may be ideal if you want a cheaper choice and are ready to maintain it. Flooded batteries have long been used for their durability and affordability. These batteries can work well in diverse applications with regular inspections, distilled water, and electrolyte density adjustments.

Factors to consider:

- Application: Determine the specific requirements of your application, such as power demands, cycling needs, and environmental conditions. This will help you choose a battery type that can handle the demands and thrive in the intended environment.

- Maintenance preferences: Consider your willingness and ability to perform regular maintenance. AGM batteries provide a maintenance-free solution, while flooded batteries require periodic inspections and maintenance.

- Budgetary considerations: Evaluate your budget and weigh the upfront cost of AGM batteries against the potential long-term savings offered by flooded batteries. While AGM batteries have a higher upfront cost, the extended lifespan and reduced maintenance requirements can lead to long-term cost savings.

| Battery Type | Pros | Cons |

|---|---|---|

| AGM Battery |

|

|

| Flooded Lead-Acid Battery |

|

|

Conclusion

In conclusion, flooded lead-acid and AGM batteries have different features, maintenance needs, and performance capabilities, emphasizing the necessity of following manufacturer specifications for best battery performance and longevity. The absence of moisture and maintenance make AGM batteries ideal for demanding applications. They can supply high current and last longer, making them suited for power demands. AGM batteries have a glass mat separator that keeps the electrolyte solution “dry” between the plates, preventing leaks even if the battery case is damaged or tilted. Traditional lead-acid flooded batteries need periodic examination and maintenance.

When selecting the appropriate battery type, it is crucial to consider the intended application, expected maintenance capabilities, and budget constraints. AGM batteries are well-suited for applications where maintenance is complex or limited, such as in recreational vehicles or boats. They excel in delivering high current and have a longer service life.

They must be charged properly and discharged to 50% of battery capacity to work best. Compared to flooded batteries, AGM batteries cost more upfront. However, flooded batteries are reliable for periodic maintenance applications like cars and backup power systems. They last longer and are easy to maintain. They need regular maintenance, can be harmed by forceful movement, and are particularly susceptible to harsh climates that shorten battery life.

FAQ

Q: What is a flooded lead-acid battery?

A: A flooded lead-acid battery is the traditional type of lead-acid battery that contains a liquid electrolyte solution triggering the chemical reaction. It requires periodic inspection and maintenance, including adding distilled water and adjusting the density of the electrolyte.

Q: How does a flooded lead-acid battery work?

A: A flooded lead-acid battery works by utilizing the liquid electrolyte solution to initiate chemical reactions. These reactions produce the electrical energy needed to power various applications. However, the battery needs regular maintenance to ensure optimal performance.

Q: What are the pros and cons of flooded lead-acid batteries?

A: Pros of flooded lead-acid batteries include an extended lifespan and lower cost. However, they require periodic inspection and maintenance, can be damaged in forceful movement, and are significantly affected by extreme climates.

Q: What is an AGM battery?

A: An AGM battery (Absorbed Glass Mat) is a type of lead-acid battery that contains a special glass mat separator, which holds the electrolyte solution between the battery plates. AGM batteries are maintenance-free and have a longer service life compared to flooded lead-acid batteries.

Q: How does an AGM battery work?

A: An AGM battery works by storing the electrolyte in a “dry” or suspended state using the glass mat separator. This design prevents spillage even if the battery case is damaged or tipped. AGM batteries can also deliver high current and have a longer service life.

Q: What are the pros and cons of AGM batteries?

A: Pros of AGM batteries include being maintenance-free, having a longer service life, and the ability to deliver high current. However, they require careful charging and have a higher upfront cost compared to flooded lead-acid batteries.

Q: How do flooded lead-acid batteries and AGM batteries compare?

A: Flooded lead-acid batteries require regular maintenance and are susceptible to damage, but they can last longer if properly taken care of. AGM batteries are maintenance-free, have a longer service life, and perform better in applications where maintenance is complex.

Q: What are some tips for choosing the right battery type?

A: When selecting a battery type, consider the intended application, expected maintenance capabilities, and budget constraints. It is important to choose a battery that aligns with these factors to ensure optimal performance and longevity.