Enhancing Auto Safety: Importance of Tracing Car Parts

Tracing car parts is crucial for safety and reliability. Unique serial numbers, barcodes, and RFID tags enable tracking and verification. Advanced tech like blockchain may create a decentralized system to record part info.

Traceability identifies potential recalls or defective components, protecting lives. It also enables better supply chain management. All stakeholders must embrace tracking systems for optimal results.

Traceability will be even more important as cars become connected and autonomous. Tracing each component will ensure smooth functioning and quick troubleshooting. An interconnected network of traceable parts will lead to safer roads and reliable vehicles.

Importance of Tracing Car Parts

Tracing car parts is essential. It ensures safety, authenticity, and stops counterfeit parts. It also helps spot manufacturing defects or recalls quickly.

In this industry, quality and safety are paramount. Tracing systems track parts from origin to installation. This helps manufacturers control quality and only use genuine components.

Traceability also combats counterfeit car parts. Advanced tracking technologies like RFID tags or unique identification codes trace parts back to source. This protects consumers from bad parts and enables authorities to catch counterfeiters.

Tracing car parts also speeds up identifying and dealing with manufacturing defects or recalls. Accurate tracking of production details means manufacturers can find faulty batches or parts that may cause accidents.

Pro Tip: When buying car parts, get products with traceability features like unique codes or RFID tags. It guarantees reliability and keeps you safe.

Methods for Tracing Car Parts

Car parts have unique serial numbers, assigned during manufacturing, so they can be traced to the vehicle they were installed in.

Labels with barcodes can be added to car parts, with info about the manufacturer and model.

Radio Frequency Identification (RFID) tags may be embedded, allowing for easy tracking and identification.

GPS technology is found in some high-end car parts, such as navigation systems or autonomous driving components. This helps with real-time location tracking.

Organizations may also keep databases that link car part info with Vehicle Identification Numbers (VINs).

Pro Tip: When tracing car parts for maintenance or recalls, check manufacturer databases for accurate and recent info.

Benefits of Tracing Car Parts

The tracing of car parts has many benefits which can improve the automotive industry. Such as better inventory management, fighting counterfeiting, promoting safety, better quality control, more efficient warranty claims processing, and aiding in accident investigations.

- Inventory Management: Tracing car parts helps manufacturers to have a clear record of their stock, making it easier to restock and meet customer needs.

- Counterfeit Prevention: This practice lets companies identify counterfeit products in the market and take steps to protect their brand.

- Consumer Safety: Tracing car parts makes it feasible to do timely recalls if there are any defective components, thus protecting consumers.

- Quality Control: With tracing systems in place, manufacturers can easily spot defects or weaknesses in particular car parts and take preventive measures to upgrade product quality.

- Warranty Claims Processing: Tracing car parts makes it easy to verify and approve warranty claims, reducing effort for both manufacturers and customers.

- Accident Investigations: Tracing car parts helps authorities investigate accidents by finding out where components come from, giving valuable data about safety or design issues.

Also, tracing car parts helps reduce environmental impact through proper disposal management. It makes sure recycled materials are handled correctly and waste is minimized.

Did you know? A study by Automotive News* found that traceability systems have cut counterfeit auto part sales by 50% in the past five years.

Adopting tracing car parts not only brings many benefits but also strengthens the automotive industry’s efficiency and reliability. By giving priority to tracing processes and installing strong systems, manufacturers can modernize their operations while providing safer vehicles to consumers.

Challenges and Limitations of Tracing Car Parts

Tracing car parts can be tough – let’s look at the issues! Here’s a table of challenges and their limitations:

| Challenge | Limitation |

|---|---|

| Counterfeit parts | Distinguishing real from fake components is tricky |

| Supply chain | Complex networks make it hard to track origins |

| Lack of standardization | Inconsistent labelling and coding can block traceability |

| Disassembly | Once installed, tracing is difficult as disassembly takes time |

Besides these issues, comprehensive databases allowing part history and ownership tracking are missing.

For successful part tracing, use unique identifiers like serial numbers or markings during production. This helps locate and identify components when needed.

By addressing these challenges, we can all help ensure safety, quality control and accountability in the automotive industry.

Conclusion

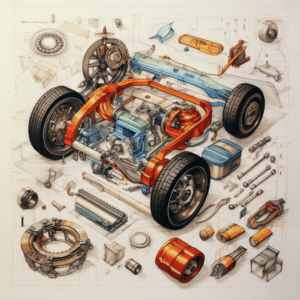

Modern tracking technologies and identification methods make car parts traceable. Such advancements allow monitoring and identifying them throughout their lifecycle.

Barcodes or QR codes can be used. Those contain info about the part, e.g. origin, manufacturing date and details.

Radio Frequency Identification (RFID) tags are small electronic devices that are embedded into car parts, enabling real-time tracking and monitoring. By scanning these tags, manufacturers, suppliers and consumers can know the whereabouts and history of a part.

Advanced software systems have been developed to enhance traceability. These use complex algorithms to analyze data from different sources, making quick and accurate identification of any part possible.

Traceability advantages the automotive industry. It prevents counterfeit products from entering the market, ensures quality control and reduces risk of costly recalls. It also provides peace of mind to consumers wanting to purchase genuine and safe car parts.

Frequently Asked Questions

Q1: Can car parts be traced?

A1: Yes, car parts can be traced using various methods. Manufacturers often assign unique identification numbers or codes to their parts, allowing them to be tracked throughout the supply chain and even after installation in a vehicle. Additionally, some car parts may have serial numbers or embedded tracking devices for easy identification and tracing.

Q2: How can I trace a specific car part?

A2: To trace a specific car part, you can start by checking if the manufacturer has provided any unique identifiers, such as part numbers or serial numbers. These identifiers can be used to track the part’s origin and distribution. You can also consult databases maintained by regulatory agencies or industry organizations that contain information about car parts and their manufacturers.

Q3: Why would someone want to trace a car part?

A3: Tracing car parts is important for several reasons. It helps in identifying counterfeit or stolen parts, ensuring the authenticity and safety of the vehicle. Tracing also aids in recalling faulty parts and assisting with warranty claims. Additionally, it streamlines the process of obtaining suitable replacements and maintaining a record of parts used in a vehicle for future reference.

Q4: Are there any legal requirements for tracing car parts?

A4: While specific legal requirements may vary by jurisdiction, many countries have regulations in place to ensure traceability of car parts. These regulations aim to curb counterfeiting, improve consumer safety, and assist with recalls. Manufacturers may be obligated to mark their parts with certain identifiers or register them in databases accessible to regulatory bodies and law enforcement agencies.

Q5: Can individual car owners trace their own car parts?

A5: Yes, individual car owners can trace their own car parts. By referring to the vehicle’s manual or consulting the manufacturer’s website, they can gather information about the parts installed in their vehicle. They can also contact authorized dealers or service centers to obtain details about specific parts. Online platforms and databases may also assist in identifying the origin and authenticity of various car parts.

Q6: How can traceability benefit the automotive industry?

A6: Traceability is highly beneficial to the automotive industry. It aids in improving product quality control, reducing counterfeit parts in the market, and ensuring the safety and reliability of vehicles. By tracing car parts, manufacturers can quickly identify and rectify faulty components, leading to more efficient recall processes. It also fosters transparency, which enhances consumer trust in the industry.