Tuning Blow Off Valves for Iconic Car Sounds

Tuning Blow Off Valves, Turbochargers are probably one of the most talked-about components in the tuning world. The explanation for this is simple: the more boost you have, the faster your car will move. The only drawback with boost is that it can cause a slew of problems if it’s tuned incorrectly. To produce more power, raising the air pressure entering the engine is critical. It does, however, put much stress on the interior components of your engine. When you remove your foot from the gas pedal, the throttle plate closes, trapping pressurised air between the intake, manifold, and the turbocharger. Modern turbocharged engines have blow-off valves to prevent internal components from being harmed by excessive air pressure.

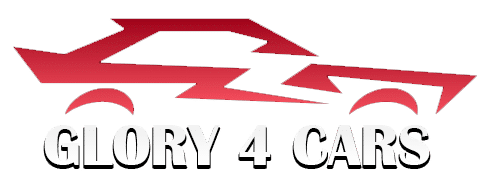

Blow-off valves are basic but essential components of every turbo engine that produces much boost. The primary function of the blow-off valves is to release pressure when the throttle plate shuts, relieving the turbocharger of its burden. Furthermore, some of these valves maintain the compressor spinning when the engine load is released, lessening the turbo lag effect when the gas pedal is pressed again.

Is It Important To Tune A Blow Off Valve?

Tuning Blow Off Valves, One of the things that many people appreciate about blow-off valves is the iconic sound they produce, in addition to the safety features they offer. Even yet, many manufacturer-installed blow-off valves are designed to be as silent as possible, permitting forced induction without causing any unnecessary noises that can prompt service or warranty concerns. As a result, you’ll need to tune your blow-off valve to achieve that distinctive sound the blow valve makes when the throttle closes.

How Can You Tune Your Blow Off Valve Properly To Get That Iconic Sound?

Vent to the Atmosphere

As previously indicated, if you purchase a car with a factory-installed blow-off valve or bypass valve, it will be completely silent. This is because the valves are designed to redistribute the vented air into the intake tract, which is muffled by the airbox. However, having a blow-off valve intended to vent straight to the atmosphere is a straightforward technique that can provide you with a more noticeable sound.

With neither intake tubing nor airboxes to soften the sound, the airflow is vented straight to the engine compartment, resulting in a much louder discharge. However, if you own a car with a mass airflow system, it is essential to note that venting your blow-off valve discharge to the atmosphere is a very unrecommended course of action. That is because venting to the air will generate unexpected too rich fuel mixtures, causing stumbling and stalling due to how these systems gauge air.

Institute a cold air intake

Cold air and short ram intakes replace OEM airboxes with a faster, more direct engine airflow path. Unfortunately, this direct airflow channel increases blow-off valve discharge noise even on factory-style recirculation systems.

Any blow-off valve vented to the air will produce a more noticeable sound, but there are drawbacks. Consider installing an intake system for the most refined balance of sound and drivability. More power and loudness can be yours at a reasonable price.

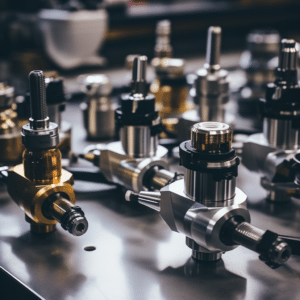

Select a Hybrid Type to Prevent Stumbling

The pressure air from hybrid blow valves is vented into the intake pre-turbo to maintain the proper fuel mixture and into the atmosphere to produce an iconic sound. This is useful in some cars where venting simply into the atmosphere causes a rich condition, resulting in stumbling.

Use The Sequential Type Valve to Enhance Throttle Response

Tuning Blow-Off Valves, Sequential pull-type valves like the super sequential valve or HKS SSQV respond faster to engine conditions than larger ones, improving throttle response. In addition, because of their design, these valves also benefit from being less susceptible to pressure leaks.

Use a Dynamometer

To obtain the best results from your tuning, you’ll require to put your automobile on a dynamometer. A dynamometer measures horsepower and torque to optimize blow-off valve settings. Adjust the blow-off valve very slowly and carefully until you get the best results.

Key Features to Consider When Buying a Blow Off Valve

Build Quality

Tuning Blow Off Valves, The blow-off valve construction quality speaks volumes about how long it will survive and operate well. Always buy those that are manufactured with a billet aluminum frame and an anodized aluminum internal piston. Anything constructed entirely of plastic should be avoided since it can break or melt under extreme strain.

Sound Quality

It’s crucial to think about the sound quality or kind you desire before purchasing a blow off valve. For example, do you prefer a quiet hissing sound or a louder hissing sound that attracts attention to your vehicle? To avoid noise complaints, make sure anything you choose is within the recommended noise rating.

Ease of Installation

Always purchase BOV’s that come with installation instructions and a mounting kit. These are easier to install than standalone products that require mounting hardware.

Compatibility

Universal fit BOVs are available, but you need investigate them to make sure they fit your car. To avoid getting the wrong size, choose custom-fit models for your car’s model, make, and year.

BOV vs. CBV

Whether or not you use a BOV is determined by how your engine handles excess air pressure. For optimum engine performance, some engines require a compressor bypass valve that directs pressured intake. Always consult your owner’s manual to determine the type of valve your car should use.

Final take

Basic but essential blow-off valves are in every turbo engine. In addition to protecting, many individuals like their unique sound. Many factory-installed blow-off valves are silent, so you’ll need to adjust them to make that sound. Maintain a properly tuned blow-off valve to prevent engine damage.